Bakelite and its use in Cameras

The first truly Synthetic Plastic

In 1907 Leo Hendrick Baekeland, a Belgian chemist working in New York, invented the first entirely synthetic plastic. It was a thermosetting phenolic resin patented in 1907 under the name Bakelite. It was made by combining phenol and formaldehyde using heat and pressure. Once the resin hardened, it could not be re-melted by the application of heat. This discovery was of profound importance and effectively gave birth to the modern plastics industry.

In 1907 Leo Hendrick Baekeland, a Belgian chemist working in New York, invented the first entirely synthetic plastic. It was a thermosetting phenolic resin patented in 1907 under the name Bakelite. It was made by combining phenol and formaldehyde using heat and pressure. Once the resin hardened, it could not be re-melted by the application of heat. This discovery was of profound importance and effectively gave birth to the modern plastics industry.

Bakelite Cameras

Camera makers soon realized that the properties of this phenolic resin were ideally suited for the use in cameras. Bakelite was opaque, sturdy, durable and could be moulded to any shape. Early Bakelite cameras tended to be phenolic imitations of their metal and cardboard counterparts. However, in 1934 something truly remarkable happened. The industrialist Walter Dorwin Teague designed a camera that was better suited to the characteristics of the new material. This was the Baby Brownie - a black phenolic box with a distinctive vertical ribbing.

Other great designs followed. The Agfa Trolix of 1936 had curved size sides, rounded corners, decorative ribs and a shiny surface all typical of the 1930s streamlining. It is made from Trolitan plastic which is the German equivalent of Bakelite. Such features would have been very difficult to realise in metal.

Another outstanding design of the period was the 1937 Purma Special. This camera took the form of an elegant curved and tapered rectangular case of Bakelite. Unlike most other models the film advance mechanism, shutter lever and shutter release button did not protrude from the body. Again, these features would have been more difficult and costly to realise in metal.

Other Plastics Used

Ebonite is a brand name for a material generically known as hard rubber, and is obtained by vulcanizing natural rubber by mixing with sulphur and linseed oil and heating for prolonged periods. Its name comes from its intended use as an artificial substitute for ebony wood. It has been used for various applications since 1851 when it was invented. It is very black and very hard and ideal for use in cameras and easily mistaken for Bakelite. An example of a camera made with this material is the Hoei Ebony 35 (1957).

Bakelite had two issues for more modern cameras of the late 40s and 50s. The material was quite heavy and could only be produced in darker colours. White or light coloured Bakelite soon faded when exposed to light turning the white Bakelite to a grubby yellow nicotine colour. So manufacturers experimented with lighter and less brittle plastics. As an example, the Spartus Full-Vue (1948) used a softer lighter non-thermoset plastic for the viewfinder cover. Unfortunately, quite a few of these vintage cameras now have viewfinder covers that are warped and distorted. Another example is the Gaevert Gevabox 6x6 (1950). The body is black Bakelite but the film advance knob and the matching knob on the other side of the camera were made from white urea formaldehyde which did not discolour when exposed to sunlight.

Is it Bakelite?

The word Bakelite was the trademark coined by the inventor. The giant Union Carbide Corporation of America, who acquired Baekeland's business, recognised the tremendous value of the mark as it was known and respected throughout the world. They used it to sell other types of plastic. So successful and dominant was the trademark, it became generic, like that of Hoover and Sellotape. In other words, many cameras described as Bakelite might well be made from thermoset phenolic materials made by another manufacturers unconnected with the Bakelite organisation.

A prime example is the Agfa Trolix camera made from Trolitan which is the German equivalent of Bakelite. Most websites will say it is made from Bakelite. So any thermoset phenolic resin has a tendency to be called Bakelite. Another example is the Zenith Comet which often quoted as being made from Bakelite. It is in fact made from a non-thermosetting plastic (It fails the hot-pin test). As far as the general public are concerned, if it's old black plastic it must be Bakelite!

Testing for Bakelite

What we are actually testing for is a camera body made from a thermoset plastic based on formaldehyde. There are several tests that can be carried out but nearly all give false positives and false negatives depending on the material tested. Non are totally conclusive. The trick is to apply a series of observations and tests to make deductions from the results. Note that some non thermoset plastics may be damaged by some of these tests. Most camera collectors are not fans of possible destructive testing!

The observations are:-

- Age

- Thickness and weight

- Flexibility

- The moulding process

The tests are:-

- The hot water test

- The rubbing test

- The Simichrome test

- The hot pin test

Age

If the camera was produced between the wars (1919-1939) then there is a good chance that it will be made of thermo-set plastic(Bakelite). After the Second World War (1945-) newer plastics became more popular.

Thickness and weight

Bakelite is a rather brittle material and it tended to be cast in greater thickness than modern plastics. It also has a greater density than modern plastics. Bakelite has a density of 1.3g/cc; polythene has a density of 0.96g/cc. The upshot of this is that Bakelite cameras tend to be heavy. For example, two similar sized cameras:- Purma Special 127 film camera (Bakelite) - weight: 365g; Zenith Comet 127 film camera (non-thermoset plastic) - weight 196g.

Flexibility

Bakelite sets hard. It tends to be fairly rigid. Other non-thermoset plastics will be more flexible and will bend and distort. For example, the back of a Purma Special is difficult to twist without cracking but the back of a Zenith Comet twists easily with very little pressure applied.

The Moulding Process

Bakelite is moulded differently than softer thermoplastics and sometimes have to be finished by hand. Check around the camera for areas that have been filed or shaped by hand. The Univex by the Spanish company Casa Univex is a good example of this. You can see where the back has been filed to fit.

Bakelite is moulded differently than softer thermoplastics and sometimes have to be finished by hand. Check around the camera for areas that have been filed or shaped by hand. The Univex by the Spanish company Casa Univex is a good example of this. You can see where the back has been filed to fit.

Thermo plastics (as apposed to thermoset plastics) are those that can be softened again if reheated. These are ideal for use in injection moulds. Again inspection will reveal the remains of the sprues and runners that were cut off after the injection process.

The Hot Water Test

Find a part of the camera that will not be damaged if run under hot water - for example a detachable back. Run the part under hot water for 30 seconds and then smell it. If it is Bakelite it will give off its characteristic musty phenol odour. Lucite will not smell, Casein will have a smell of burning milk and Ebonite will smell like burning rubber. Modern plastics won't smell at all. However, some plastics can be damaged by very hot water, so you need to be fairly sure what you are testing is likely to be Bakelite. For instance, hot water testing on the viewfinder cover of a Spartus Full-Vue (1948) could warp and damage it.

The Rubbing Test

Rub a part of the camera vigorously with your thumb until it gets really hot. This will allow the Bakelite to give off its characteristic musty phenol odour. Again other plastics will give off their own characteristic smell.

The Simichrome Test

Simichrome is a metal polish which will react with phenolic products. Simichrome is a pink cream that when rubbed on Bakelite will turn yellow. Put a small amount on a cotton bud and rub an inconspicuous area. The Simichrome reacts to Bakelite that has oxidised and so it is important to choose an area that has not been polished recently or coated. This is a standard and reliable test for most Bakelite products but unfortunately not for black Bakelite. The black tends to mask the response. You are more likely to get a false negative with this test when used on black cameras but if you choose your test spot carefully then you will see the tell-tale nicotine yellow colour.

Simichrome is a metal polish which will react with phenolic products. Simichrome is a pink cream that when rubbed on Bakelite will turn yellow. Put a small amount on a cotton bud and rub an inconspicuous area. The Simichrome reacts to Bakelite that has oxidised and so it is important to choose an area that has not been polished recently or coated. This is a standard and reliable test for most Bakelite products but unfortunately not for black Bakelite. The black tends to mask the response. You are more likely to get a false negative with this test when used on black cameras but if you choose your test spot carefully then you will see the tell-tale nicotine yellow colour.

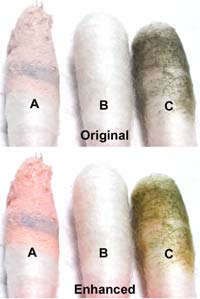

Image Enhancement

Very often the response you get from Simichrome is muted. This is because the black fillers mask the colour. If you have a photo editor like photoshop which enables you to increase the saturation of an image then you might try this. Get three cotton buds. Do the Simichrome test as usual with one of the buds (C). Apply a light coat of Simichrome to another bud (A). Leave the third untouched (B). Take an image of the three buds. Import the image into your photo editor. Change the white balance until the untouched bud registers as white. Now slightly increase the saturation. Any yellowing of the bud that has been rubbed on Bakelite will be enhanced. Ensure that the untouched bud stays white. The response shown was when testing a Kodak Brownie 127.

The Hot Pin Test

This test is not to be undertaken lightly and can be the most destructive. If the camera is Bakelite then not much damage will be done, but if it is not a thermoset plastic then it will melt. Heat up a pin held in pliers with a flame until it is very hot and apply it to the camera in a place that will not show - somewhere inside. If there is no indentation made in the material and it does not melt, then it is a thermoset plastic - Bakelite.

This test is not to be undertaken lightly and can be the most destructive. If the camera is Bakelite then not much damage will be done, but if it is not a thermoset plastic then it will melt. Heat up a pin held in pliers with a flame until it is very hot and apply it to the camera in a place that will not show - somewhere inside. If there is no indentation made in the material and it does not melt, then it is a thermoset plastic - Bakelite.

See the results of a test on the inside of the back of a Zenith Comet made from a non thermoset plastic. Don't worry, this is only the size of a pin-hole.